A Care And Maintenance Guide For Your Carbon Brushes

The significance of carbon brushes is immense in various applications. They are the heartbeat of many electric motors and generators.

The significance of carbon brushes is immense in various applications. They are the heartbeat of many electric motors and generators. Thus, taking care of these vital parts is key to ensuring optimal performance.

This guide aims to provide comprehensive instructions on the care and maintenance of carbon brushes.

Understanding The Role And Maintenance Of Carbon Brushes

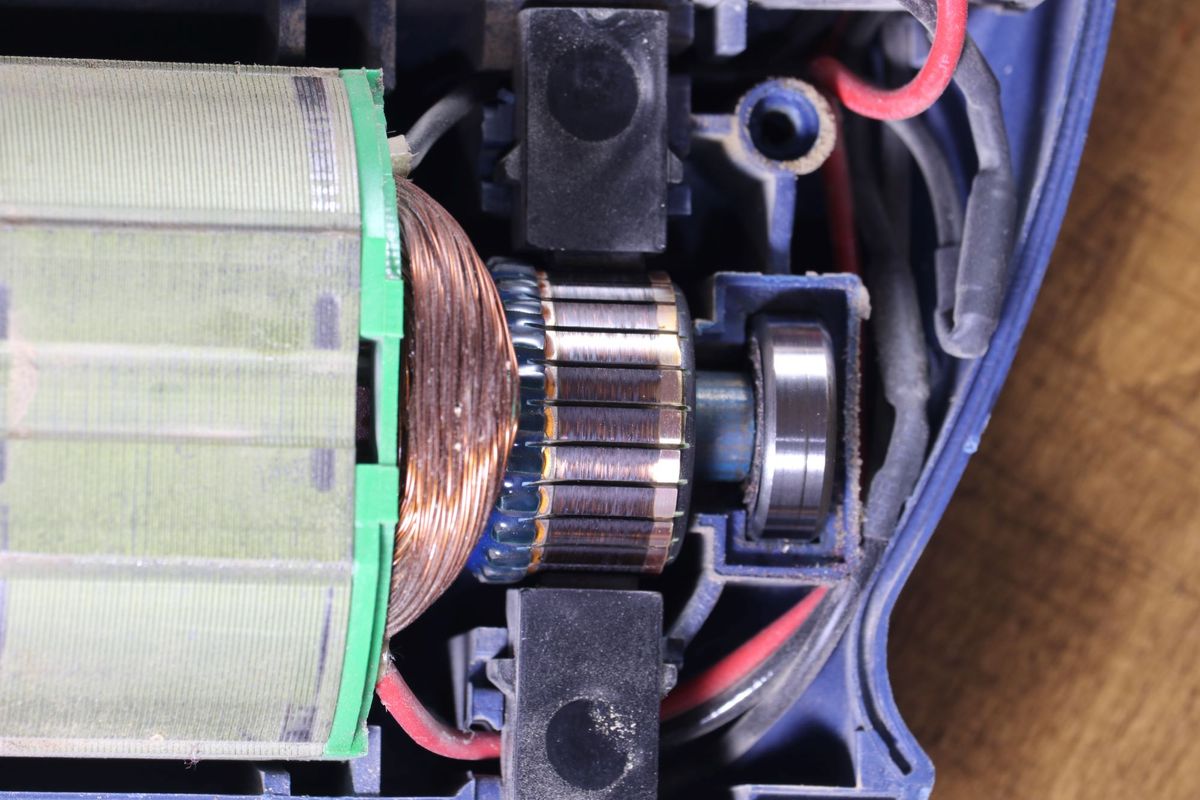

Before we dive into the care aspect, it's crucial to understand the nature and role of carbon brushes in electrical appliances. Also known as electric motor brushes, these vital components of an electric motor facilitate electrical conduction between the stationary wires (stator) and the rotating wires (rotor). In a typical motor or generator, you'll often find several carbon brushes, each made up of at least one carbon block and one shunt or terminal, working together.

The role of these components extends beyond just facilitating electrical conduction. Their condition and maintenance practices can directly impact the lifespan and performance of your electrical appliances. A well-maintained carbon brush ensures a smooth electrical current transfer, improving overall motor performance. Thus, recognizing this correlation underlines the importance of regular upkeep for these vital components.

Proper maintenance of your carbon brushes is a multi-faceted approach that brings numerous benefits:

- Extends Lifespan: Through regular inspections, cleaning, timely replacements, and appropriate lubrication.

- Improves Efficiency: Ensuring a smooth transfer of electrical current for more efficient operation of your appliances.

- Prevents Malfunctions: Avoids equipment downtime and costly repairs or replacements.

- Maintains Power Quality: Regular power supply monitoring to prevent unnecessary stress and wear on your brushes.

- Increases Longevity Of Appliances: Adherence to the manufacturer's guidelines extends the lifespan of your brushes and ensures the optimal performance of your appliances.

The detailed procedures and guidelines discussed can contribute to these benefits, helping you get the most out of your motor and, in turn, your appliances.

Now that we understand what carbon brushes are and their essential role, it's important to discuss the source and selection process, as choosing the right brush significantly affects their performance.

Sourcing New Carbon Brushes

Despite the best maintenance practices, there will come a time when your carbon brushes need to be replaced. TDO Carbon is a retailer based in the UK that offers a range of new carbon brushes for power tools like angle grinders and drills. Their selection of high-quality brushes can cater to a variety of needs, ensuring that you can find the right replacement for your specific appliance.

Therefore, it's essential to source new, high-quality carbon brushes to maintain the optimal performance of your electrical appliances.

Choosing The Right Carbon Brushes

Selecting the right brush is another crucial factor in maintaining your carbon brushes' performance. Various types of motors require different kinds of brushes. Therefore, understanding your motor's needs is key to choosing the appropriate carbon brush.

Let's explore more deeply how these different types of carbon brushes are designed to cater to the varying needs of different motors.

- Carbon Graphites: These brushes are typically used on older, slower equipment that doesn't exceed surface speeds of 4,000 feet per minute. Although they find application in metal contacts and bases, their usage in commutators is less common because of the substantial friction they create.

- Electrographites: Being subjected to high-temperature processing, these brushes possess enhanced durability, making them perfect for use in commutators. With treatment involving either organic or inorganic materials, their robustness is further increased. They are best suited for environments with high temperatures and low humidity levels.

- Graphites: Produced by combining natural or synthetic graphite with resin or pitch; they’re commonly found in commutators and slip rings. Due to their high density and low porosity, they are optimally suited for environments prone to contamination.

- Metal Graphites: By fusing graphite with fine powders of metals like copper, silver, tin, and lead, these brushes are created. Their distinct characteristic of low resistivity enhances their versatility.

This is just the beginning. Once you've made your choice, it's essential to keep a close eye on your brushes to ensure they're performing optimally.

Recognizing The Signs Of Wear And Tear

Being aware of the signs of wear and tear on your carbon brushes is the first step in their maintenance. If you notice sparks, poor motor performance, or decreased electrical conductivity, it might be time to inspect your brushes.

Regular Inspection: A Key To Maintenance

Regular inspection is a proactive step that can help prevent minor issues from escalating into major problems. This process involves checking the brush for wear and tear, ensuring it isn't too loose or tight in its holder, and confirming that it's not cracked or damaged. By doing so, you can preserve the longevity and performance of your equipment.

In addition to regular inspections, maintaining cleanliness is another critical component of carbon brush maintenance.

Cleaning Carbon Brushes: Keeping Them Clean

Cleaning is another fundamental aspect of carbon brush maintenance. Dust and debris can accumulate on the brushes over time, reducing their efficiency. It's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface.

Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced.

Replacing Carbon Brushes: Knowing When It's Time To Change

When wear and tear become too severe, replacement becomes necessary. Understanding when and how to replace your carbon brushes is a crucial part of their maintenance. Always replace them with high-quality equivalents to maintain optimal performance. Similarly, activemyhome.com is another resource where you can explore related topics.

Alongside replacement, another critical aspect of maintenance that aids in extending the life of carbon brushes is lubrication.

The Role Of Lubrication In Maintenance

Lubrication is critical in maintaining carbon brushes, reducing wear and tear and enhancing lifespan. The right lubrication reduces friction, which in turn minimizes wear on the brushes.

A Safe Environment: The Impact Of Operating Conditions

The environment in which the motor operates can significantly impact the lifespan and effectiveness of carbon brushes. Factors such as temperature, humidity, and dust or chemicals should be controlled to ensure these components' optimal performance and longevity.

Just as the operating environment impacts the brushes' effectiveness, the storage conditions, when not in use, are equally crucial for their longevity.

Proper Storage: Don't Neglect It

Proper storage of carbon brushes when they're not in use is often overlooked but is just as important as any other maintenance practice. Storing them in a dry, cool place away from corrosive materials can greatly extend their useful life.

Maintenance Procedures For Carbon Brushes

Proper care for carbon brushes is crucial to avoid equipment malfunctions and downtime. Here are some recommended procedures:

- Verify the absence of any visible damage or dirt on the brush.

- Ascertain that the brushes have the freedom to move within their holders.

- Examine the springs of each brush, making necessary adjustments to the pressure.

- Look over the commutator for signs of the following:

- Mica- A naturally occurring group of silicate minerals widely used in electrical and electronics industries due to their thermal and electrical insulating properties.

- Fins- Refers to protrusions on the commutator segments, which can be caused by incorrect installation or excessive heat.

- Slugs- Refers to foreign material or debris that can build up and cause disruption in the operation of electrical equipment.

- Ensure no commutator segments show signs of blackening, pitting, or burning.

- Examine the commutators for circularity and any deviations from bar to bar.

- Confirm the proper connection of the risers.

- Assess the brush drop or the machine's field-form curve when operating under normal load.

- Determine whether the brushes are vibrating by placing a piece of insulating material atop the brush.

- Ensure the bearings do not exhibit excessive vibration.

Consistent cleaning of motors using an air compressor can effectively prevent many of these complications. If the problem continues despite implementing the above procedures, contact the carbon brush manufacturer or your distributor. It might be necessary to service or replace your brushes.

Incorporating Technology In Maintenance

In the age of technology, incorporating it into your maintenance routine can be immensely beneficial. Advanced tools and software are now available to help monitor the condition of your carbon brushes, alerting you to any potential problems before they become severe. These tools can significantly simplify maintenance and help prevent costly repairs or replacements.

While technological aids are highly beneficial, one should not forget the importance of basic prerequisites like a stable, clean power supply for carbon brush longevity.

The Impact Of Power Quality On Carbon Brushes

The quality of the power supply can directly impact your carbon brushes' lifespan and efficiency. A steady, clean power supply ensures that your brushes aren't subjected to unnecessary stress and wear. Therefore, monitoring your power quality regularly is crucial to protect your carbon brushes and increase their longevity.

Apart from maintaining a quality power supply, following the manufacturer's guidelines for carbon brush maintenance is equally important.

The Relevance Of Manufacturer's Guidelines

The manufacturer's guidelines are fundamental for maintaining your carbon brushes. They provide detailed instructions beyond the brushes' basic care, cleaning, and replacement. These instructions are tailored specifically for the product you have, making them an invaluable tool for maintaining and enhancing the functionality of your devices.

Adhering to these guidelines is essential, as each carbon brush can have different needs depending on its design and intended use. Using the wrong maintenance techniques or replacing brushes incorrectly can lead to inefficiencies or even damage.

In short, the manufacturer's guidelines act as a key tool in ensuring the efficient operation of your carbon brushes by providing necessary information tailored to your product's specific needs and requirements. By understanding the unique needs of your specific product and adhering to the manufacturer's guidelines, you can ensure optimal operation of your carbon brushes and, consequently, your electrical appliances.

Conclusion

Maintaining your carbon brushes is crucial to ensuring the longevity and efficiency of your electrical appliances. Regular inspections, proper cleaning, timely replacements, adequate lubrication, and careful attention to operating conditions and storage can significantly enhance their performance. By adhering to the steps outlined in this guide, you can reap the numerous benefits of proper carbon brush maintenance, from extending their lifespan to improving the efficiency and longevity of your appliances.

Comments ()